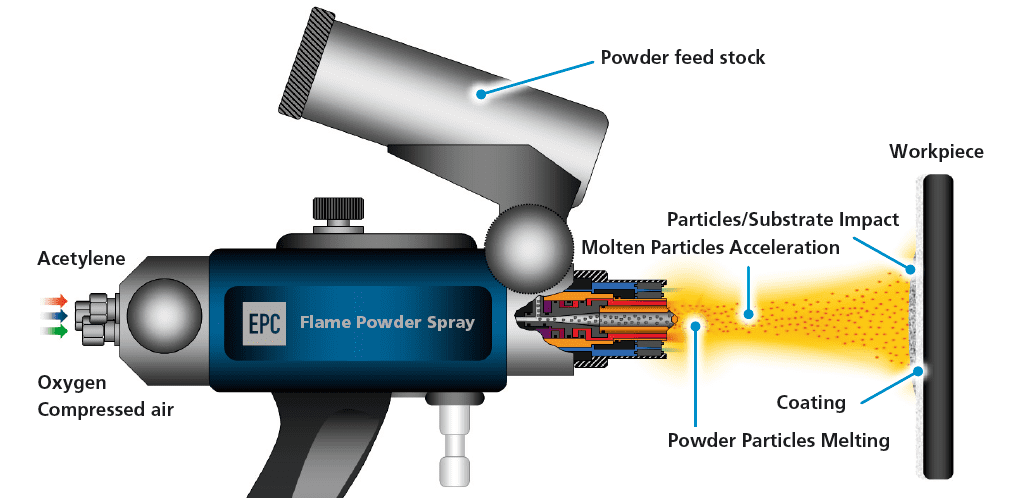

The spray material is fed continuously into the middle of the flame via an inert carrier gas. The flame consists of oxygen and a fuel gas, either acetylene or hydrogen depending on the melting point of the material to be sprayed and typically can achieve temperatures in excess of 3,000°C. When the spray stream is passed across the surface of the substrate material, the molten material rapidly cools forming a coating.

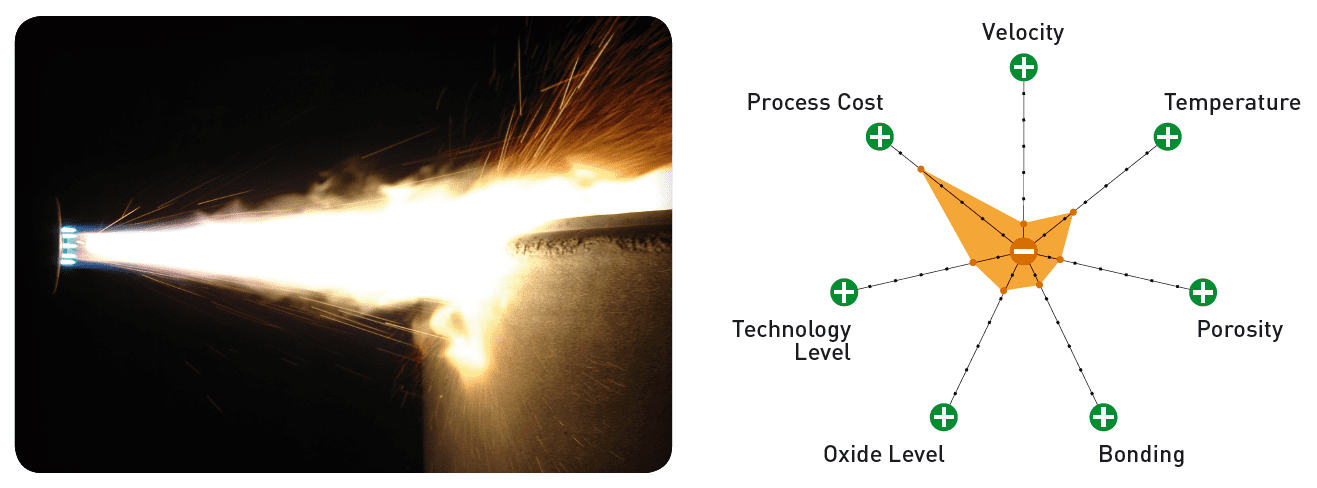

The combustion spraying process, compared with others, is relatively low energy and can be used to spray substrates that cannot be exposed to high temperatures. This can help when component distortion and structural damage is an issue. There are two forms of combustion spraying, using powder or wire stock material, each suited to different applications.

Combustion spraying can be used to make repairs, improve efficiency and restore dimensions. It is often a cost-effective method when repairs are required to high cost components. It is most often used for applying coatings that have high oxide and porosity levels and can be used to achieve rough coatings. They also provide very low stress coatings, therefore allowing very thick coatings to be applied.